Table of Contents

Point Bearing Capacity of Steel Plastic Geogrid

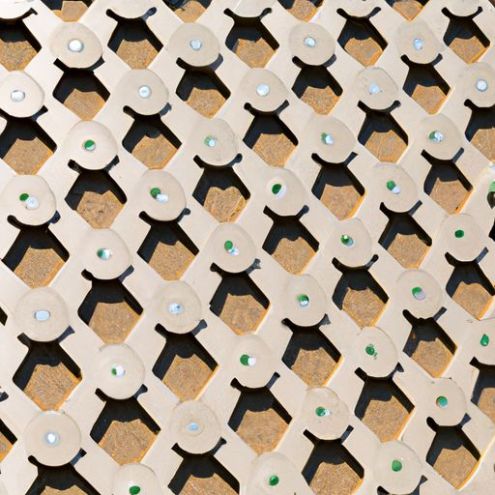

Steel plastic Geogrids are a type of geosynthetic material that is commonly used in civil engineering projects for soil reinforcement and stabilization. One of the key properties of steel plastic geogrids is their high point bearing capacity, which refers to the ability of the geogrid to distribute loads over a small area without causing deformation or failure. This property is crucial in applications where heavy loads are placed on the geogrid, such as in road construction or retaining wall design.

The point bearing capacity of a steel plastic geogrid is determined by several factors, including the type and quality of the materials used in its construction, the design of the geogrid, and the method of installation. Steel plastic geogrids are typically made from high-strength steel wires that are coated with a layer of Polymer material to protect them from corrosion and abrasion. This combination of materials gives the geogrid its high tensile strength and stiffness, which are essential for withstanding heavy loads.

In addition to the materials used in its construction, the design of a steel plastic geogrid also plays a crucial role in determining its point bearing capacity. The spacing and orientation of the steel wires in the geogrid, as well as the thickness of the polymer coating, all affect the geogrid’s ability to distribute loads evenly and resist deformation. Proper installation of the geogrid, including ensuring that it is securely anchored to the soil and that any seams are properly overlapped and welded, is also essential for maximizing its point bearing capacity.

One of the key advantages of steel plastic geogrids is their high resistance to aging and environmental factors. The polymer coating on the steel wires helps to protect them from corrosion, UV radiation, and other forms of degradation, ensuring that the geogrid maintains its strength and stiffness over time. This resistance to aging is particularly important in applications where the geogrid will be exposed to harsh environmental conditions, such as in road construction or landfill design.

Another important property of steel plastic geogrids is their high separation force of joint, which refers to the ability of the geogrid to resist lateral movement and maintain its integrity when subjected to shear forces. This property is crucial in applications where the geogrid is used to stabilize slopes or embankments, as it helps to prevent soil erosion and slope failure. The high separation force of joint of steel plastic geogrids is achieved through the combination of the high tensile strength of the steel wires and the frictional resistance of the polymer coating, which work together to hold the soil in place and prevent it from sliding or collapsing.

In conclusion, the point bearing capacity and high separation force of joint of steel plastic geogrids make them an ideal choice for a wide range of civil engineering applications. Their high tensile strength, stiffness, and resistance to aging and environmental factors ensure that they can withstand heavy loads and harsh conditions, while their ability to resist lateral movement and maintain their integrity under shear forces makes them an effective solution for soil stabilization and reinforcement. By understanding the key properties of steel plastic geogrids and how they contribute to their performance, engineers and designers can make informed decisions about the use of these materials in their projects.