Table of Contents

Benefits of Upgrading to a 3.2KW ER20 Metal CNC Spindle for Metal Milling

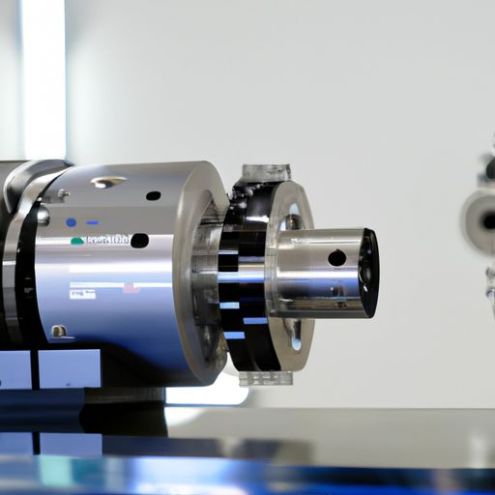

In the world of CNC Machining, having the right spindle can make all the difference in the quality and efficiency of your work. One of the latest advancements in spindle technology is the 3.2KW ER20 Metal CNC Spindle, which offers a range of benefits for metal milling applications. This powerful spindle is designed to provide precision and reliability, making it an ideal choice for CNC engraving machines and metal milling operations.

In the world of CNC Machining, having the right spindle can make all the difference in the quality and efficiency of your work. One of the latest advancements in spindle technology is the 3.2KW ER20 Metal CNC Spindle, which offers a range of benefits for metal milling applications. This powerful spindle is designed to provide precision and reliability, making it an ideal choice for CNC engraving machines and metal milling operations.

One of the key advantages of upgrading to a 3.2KW ER20 Metal CNC Spindle is its increased power and performance capabilities. With a maximum power output of 3.2KW, this spindle is capable of handling a wide range of cutting tasks with ease. Whether you are working with Aluminum, steel, or other metals, this spindle can deliver the power and precision needed to achieve high-quality results.

In addition to its power, the ER20 Metal CNC Spindle also offers improved speed and efficiency. With a maximum speed of 24000 RPM, this spindle can quickly and accurately cut through metal materials, reducing machining time and increasing productivity. This increased speed and efficiency can help you complete projects faster and more efficiently, saving you time and money in the long run.

Another benefit of the 3.2KW ER20 Metal CNC Spindle is its versatility and compatibility with a wide range of CNC machines. Whether you are using a CNC router, engraving machine, or milling machine, this spindle can easily be integrated into your existing setup, allowing you to take advantage of its advanced capabilities without the need for major modifications or upgrades.

Furthermore, the ER20 Metal CNC Spindle is designed for durability and longevity, ensuring that it can withstand the rigors of heavy-duty metal milling operations. Made from high-quality materials and precision-engineered for optimal performance, this spindle is built to last, providing you with reliable and consistent results for years to come.

In addition to its power, speed, efficiency, and durability, the 3.2KW ER20 Metal CNC Spindle also offers enhanced precision and accuracy. With its advanced design and construction, this spindle can deliver precise cuts and intricate designs with minimal margin for error. This level of precision is essential for metal milling applications, where even the smallest deviation can result in costly mistakes.

Overall, upgrading to a 3.2KW ER20 Metal CNC Spindle for metal milling applications can offer a range of benefits, including increased power, speed, efficiency, versatility, durability, precision, and accuracy. Whether you are a hobbyist or a professional machinist, investing in this advanced spindle can help you take your CNC machining capabilities to the next level, allowing you to achieve superior results and maximize your productivity.

Tips for Optimizing Performance of a 8 Axis CNC Router Spindle Motor for CNC Engraving Machine

When it comes to CNC engraving machines, the spindle motor plays a crucial role in determining the overall performance and efficiency of the machine. The new 3.2KW ER20 Metal CNC Spindle 8 axis set is a powerful and versatile option for metal milling applications. With its high power output and precision engineering, this spindle motor is designed to deliver exceptional results in a wide range of engraving tasks.

To optimize the performance of your 8 axis CNC router spindle motor, there are several key tips to keep in mind. First and foremost, it is important to ensure that the spindle motor is properly installed and calibrated. This includes making sure that the motor is securely mounted to the machine and that all connections are properly tightened and secured. Additionally, it is essential to check the alignment of the spindle motor to ensure that it is running true and straight.

Another important factor to consider when optimizing the performance of your spindle motor is the selection of the right cutting tools. The type of tool you use can have a significant impact on the quality of the engraving and the overall efficiency of the machine. It is important to choose cutting tools that are appropriate for the material you are working with and that are compatible with the spindle motor you are using. Using the wrong cutting tools can result in poor quality engraving, increased wear and tear on the spindle motor, and reduced overall efficiency.

In addition to selecting the right cutting tools, it is also important to pay attention to the speed and feed rates when operating your CNC engraving machine. The speed at which the spindle motor rotates and the rate at which the cutting tool moves across the material can have a significant impact on the quality of the engraving and the overall efficiency of the machine. It is important to experiment with different speed and feed settings to find the optimal combination for your specific application.

Regular maintenance and cleaning of your spindle motor are also essential for optimizing its performance. Over time, dust, debris, and other contaminants can build up on the motor and affect its operation. It is important to regularly clean the motor and lubricate any moving parts to ensure smooth and efficient operation. Additionally, it is important to regularly check for any signs of wear or damage and address any issues promptly to prevent further damage and ensure the longevity of the motor.

Finally, it is important to stay up to date on the latest advancements in spindle motor technology and techniques for optimizing performance. By staying informed and continuously learning about new developments in the field, you can ensure that you are getting the most out of your CNC engraving machine and achieving the best possible results.

In conclusion, optimizing the performance of your 8 axis CNC router spindle motor for CNC engraving machine requires attention to detail, proper installation and calibration, selection of the right cutting tools, careful adjustment of speed and feed rates, regular maintenance and cleaning, and staying informed about the latest advancements in spindle motor technology. By following these tips and best practices, you can maximize the efficiency and effectiveness of your spindle motor and achieve exceptional results in your engraving tasks.