Table of Contents

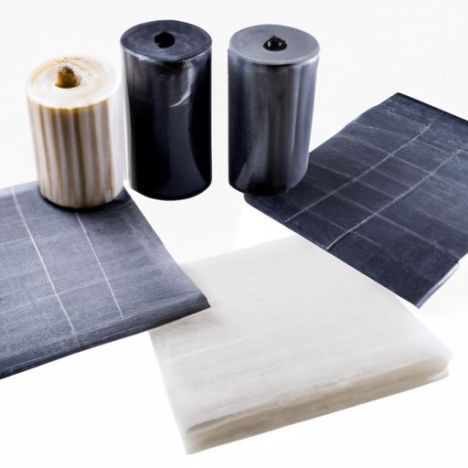

Customizable Needle Felt Filter Precision for Various Micron Steel Woven Wire Variety

Needle felt Filters are an essential component in many industrial processes, providing a reliable means of removing contaminants and impurities from liquids and gases. These filters come in a variety of materials and micron ratings to suit different applications, with precision being a key factor in their effectiveness. In this article, we will explore the benefits of customizable needle felt filters, specifically designed for various micron steel woven wire varieties.

One of the key advantages of needle felt filters is their ability to be customized to meet specific filtration requirements. This customization allows for the selection of the most suitable material and micron rating for a particular application, ensuring optimal filtration performance. For applications where a high level of precision is required, such as in the pharmaceutical or Food And Beverage industries, needle felt filters with micron ratings of 1, 2, 3, 5, or 15 are commonly used.

The use of steel woven wire in needle felt filters provides added durability and strength, making them ideal for applications where high temperatures or abrasive materials are present. Steel woven wire filters are known for their excellent filtration efficiency and long service life, making them a popular choice in industries such as petrochemical, automotive, and manufacturing.

In addition to steel woven wire, needle felt filters can also be made from cellulose filtration material. Cellulose filters are known for their high dirt-holding capacity and excellent flow rates, making them ideal for applications where a high level of filtration efficiency is required. Cellulose filters are also resistant to Chemicals and moisture, making them suitable for use in a wide range of industrial applications.

For applications where high temperatures are a concern, non-woven needle felt filters are an excellent choice. These filters are designed to withstand temperatures of up to 500 degrees Fahrenheit, making them ideal for use in applications such as hot gas filtration, industrial ovens, and incinerators. Non-woven needle felt filters are also resistant to chemicals and abrasion, making them a versatile option for a wide range of industrial applications.

One of the key benefits of customizable needle felt filters is their versatility. These filters can be tailored to meet the specific requirements of a wide range of applications, making them a cost-effective and efficient filtration solution. Whether you need a filter with a specific micron rating, material composition, or temperature resistance, customizable needle felt filters can be designed to meet your exact specifications.

In conclusion, customizable needle felt filters offer a versatile and efficient filtration solution for a wide range of industrial applications. With options for various micron steel woven wire varieties, cellulose filtration, and high-temperature non-woven materials, these filters can be tailored to meet the specific requirements of any application. Whether you need a filter for precision filtration, high-temperature applications, or chemical resistance, customizable needle felt filters provide a reliable and cost-effective solution for your filtration needs.

Cellulose Filtration in High Temperature Non-Woven Needle Felt Filters

Needle felt filters are an essential component in many industrial processes, providing a means of separating particles from liquids or gases. These filters come in a variety of materials and configurations to suit different applications, with cellulose filtration in high temperature non-woven needle felt filters being a popular choice for many industries.

Cellulose filtration is a process that involves using cellulose fibers to capture and remove particles from a fluid stream. Cellulose is a natural material that is known for its high absorption capacity and ability to trap particles of various sizes. When used in needle felt filters, cellulose fibers are compressed and bonded together to create a dense, porous material that is highly effective at filtering out contaminants.

High temperature non-woven needle felt filters are designed to withstand extreme temperatures, making them ideal for applications where filtration is required in hot environments. These filters are made from synthetic fibers that are resistant to heat, ensuring that they maintain their integrity and filtration efficiency even when exposed to high temperatures.

One of the key advantages of cellulose filtration in high temperature non-woven needle felt filters is their customizable nature. These filters can be tailored to meet specific filtration requirements, with options available for different micron ratings, flow rates, and particle retention capacities. This flexibility allows industries to optimize their filtration processes and achieve the desired level of cleanliness in their systems.

In addition to their customizable nature, cellulose filtration in high temperature non-woven needle felt filters offers excellent filtration efficiency. The dense structure of the filter material ensures that particles are captured and retained, preventing them from contaminating the fluid stream. This high level of filtration efficiency is essential for industries that require clean fluids for their processes.

Furthermore, cellulose filtration in high temperature non-woven needle felt filters is a cost-effective solution for many industries. The filters are durable and long-lasting, reducing the need for frequent replacements and maintenance. This not only saves on costs but also minimizes downtime and ensures continuous operation of industrial processes.

Another benefit of cellulose filtration in high temperature non-woven needle felt filters is their ease of installation and use. These filters can be easily integrated into existing filtration systems, allowing for seamless operation without the need for extensive modifications. This makes them a convenient and practical choice for industries looking to improve their filtration processes.

In conclusion, cellulose filtration in high temperature non-woven needle felt filters offers a reliable and efficient solution for industries requiring precise filtration in hot environments. With their customizable nature, excellent filtration efficiency, cost-effectiveness, and ease of installation, these filters are a popular choice for a wide range of applications. By choosing cellulose filtration in high temperature non-woven needle felt filters, industries can ensure the cleanliness and integrity of their fluid streams, leading to improved performance and productivity.