Table of Contents

Benefits of Upgrading to a Small Toilet Paper Corrugated Cardboard Production Line

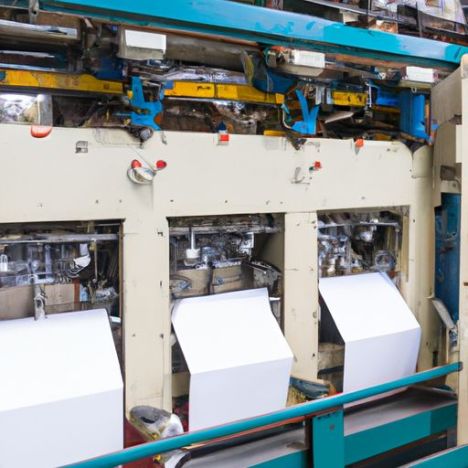

In today’s fast-paced world, efficiency and productivity are key factors in the success of any business. This is especially true in industries that rely on the production of paper products, such as napkins, toilet paper, and corrugated cardboard. Upgrading to a small toilet paper corrugated cardboard production line can offer a wide range of benefits for businesses looking to streamline their operations and increase their output.

One of the primary benefits of upgrading to a small toilet paper corrugated cardboard production line is increased efficiency. These production lines are designed to automate many of the processes involved in paper product manufacturing, reducing the need for manual labor and increasing the speed at which products can be produced. This can help businesses meet growing demand and improve their overall productivity.

In addition to increased efficiency, upgrading to a small toilet paper corrugated cardboard production line can also Lead to cost savings. By automating processes and reducing the need for manual labor, businesses can lower their production costs and improve their bottom line. This can make a significant impact on the profitability of a business, allowing them to reinvest in other areas of their operations or pass on savings to customers.

Another benefit of upgrading to a small toilet paper corrugated cardboard production line is improved product quality. These production lines are designed to produce consistent, high-quality products that meet industry standards. This can help businesses build a strong reputation for quality and reliability, leading to increased customer satisfaction and loyalty.

Furthermore, upgrading to a small toilet paper corrugated cardboard production line can also help businesses stay competitive in the market. With increasing competition in the paper product industry, businesses need to find ways to differentiate themselves and stand out from the competition. By investing in a modern production line, businesses can improve their efficiency, reduce costs, and enhance product quality, giving them a competitive edge in the market.

Additionally, upgrading to a small toilet paper corrugated cardboard production line can also help businesses reduce their environmental impact. Many modern production lines are designed to be more energy-efficient and produce less waste, helping businesses reduce their carbon footprint and operate in a more sustainable manner. This can be an important consideration for businesses looking to meet the growing demand for environmentally-friendly products.

Overall, upgrading to a small toilet paper corrugated cardboard production line can offer a wide range of benefits for businesses in the paper product industry. From increased efficiency and cost savings to improved product quality and environmental sustainability, investing in a modern production line can help businesses streamline their operations, increase their output, and stay competitive in the market. By making the switch to a small toilet paper corrugated cardboard production line, businesses can position themselves for long-term success and growth in the industry.

How to Optimize Efficiency in a Paper Making Machine Product Line

In the world of paper production, efficiency is key. Whether you are producing napkins, toilet paper, corrugated cardboard, or any other paper product, optimizing your production line is essential to maximizing output and minimizing costs. One way to achieve this is by ensuring that your paper making machine product line is running at its highest efficiency.

One of the first steps in optimizing efficiency in a paper making machine product line is to regularly inspect and maintain your equipment. This includes checking for any signs of wear and tear, lubricating moving parts, and replacing any worn-out components. By keeping your machinery in top condition, you can prevent breakdowns and downtime, which can significantly impact your production output.

Another important factor in optimizing efficiency is to streamline your production process. This can be achieved by analyzing each step in the production line and identifying any bottlenecks or inefficiencies. By reorganizing the workflow, adjusting machine settings, or implementing automation where possible, you can increase the overall efficiency of your production line.

Additionally, investing in the latest technology and equipment can also help improve efficiency in a paper making machine product line. Newer machines are often more energy-efficient, faster, and more reliable than older models, allowing you to produce more paper in less time. By staying up-to-date with the latest advancements in paper making technology, you can ensure that your production line is operating at its peak performance.

Furthermore, training your staff on best practices and proper machine operation is crucial in optimizing efficiency. By providing your employees with the necessary skills and knowledge, they can help identify and address any issues that may arise during production. Regular training sessions and refresher courses can also help improve overall efficiency and productivity in your paper making machine product line.

In addition to maintaining and optimizing your equipment and processes, it is also important to monitor key performance Indicators (KPIs) to track the efficiency of your production line. By analyzing metrics such as production output, downtime, waste, and energy consumption, you can identify areas for improvement and make informed decisions to optimize efficiency.

Lastly, fostering a culture of continuous improvement within your organization can help drive efficiency in your paper making machine product line. Encouraging feedback from employees, implementing suggestions for improvement, and regularly reviewing and updating your processes can help ensure that your production line is always operating at its best.

Lastly, fostering a culture of continuous improvement within your organization can help drive efficiency in your paper making machine product line. Encouraging feedback from employees, implementing suggestions for improvement, and regularly reviewing and updating your processes can help ensure that your production line is always operating at its best.

In conclusion, optimizing efficiency in a paper making machine product line requires a combination of regular maintenance, process improvement, technology upgrades, employee training, performance monitoring, and a commitment to continuous improvement. By implementing these strategies, you can maximize the output of your production line, reduce costs, and stay competitive in the ever-evolving paper industry.