Table of Contents

Benefits of Using Track Chain in Heavy Machinery

Track Chains are an essential component in heavy machinery, providing stability and traction for vehicles such as Bulldozers, Excavators, and other construction equipment. These chains are designed to withstand the rigors of tough terrains and heavy loads, making them a crucial part of ensuring the efficiency and Safety of these machines.

One of the key benefits of using track chains in heavy machinery is their durability. Made from high-quality materials such as Alloy Steel, these chains are built to last and can withstand the wear and tear of constant use in challenging environments. This durability not only extends the lifespan of the machinery but also reduces the need for frequent maintenance and repairs, saving both time and money in the long run.

In addition to their durability, track chains also provide superior traction, allowing heavy machinery to navigate rough terrain with ease. The design of these chains ensures that the vehicle’s weight is evenly distributed, preventing slippage and improving stability on uneven surfaces. This enhanced traction is crucial for maintaining control and maneuverability, especially in construction sites or mining operations where precision and safety are paramount.

Furthermore, track chains help to reduce ground pressure, minimizing damage to the terrain and protecting the Environment. By spreading the weight of the machinery over a larger surface area, these chains prevent soil compaction and erosion, preserving the integrity of the Land and reducing the impact of heavy machinery on delicate ecosystems. This eco-friendly feature makes track chains a sustainable choice for construction companies and other industries that rely on heavy equipment.

Another advantage of using track chains in heavy machinery is their versatility. These chains come in various sizes and configurations to suit different types of vehicles and applications, allowing for customization based on specific needs and requirements. Whether it’s for a compact excavator or a large bulldozer, there is a track chain available to optimize performance and efficiency for any machine.

Moreover, track chains are easy to install and maintain, making them a convenient option for busy construction crews and equipment operators. With proper care and regular inspections, these chains can continue to perform at their best, ensuring smooth operation and minimizing downtime due to mechanical issues. This reliability is crucial for meeting project deadlines and maximizing productivity on the job site.

In conclusion, track chains play a vital role in the functionality and performance of heavy machinery, offering a range of benefits that contribute to the overall efficiency and safety of these vehicles. From their durability and traction to their eco-friendly design and versatility, track chains are an essential component for any construction or mining operation. By investing in high-quality track chains, companies can ensure the longevity and reliability of their equipment, ultimately leading to cost savings and improved productivity in the long term.

The Advantages of Horizontal Hydraulic Powder Forming in Manufacturing Industry

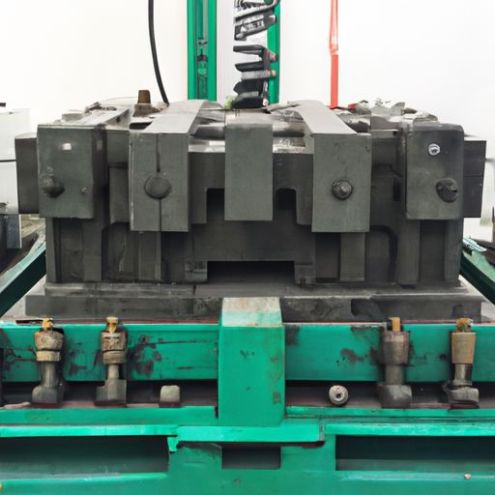

Horizontal hydraulic powder forming is a cutting-edge technology that has revolutionized the manufacturing industry. This process involves using a hydraulic press to compress powdered materials into a desired shape. One of the key advantages of horizontal hydraulic powder forming is its ability to produce complex and intricate parts with high precision and accuracy. This makes it an ideal choice for industries that require components with tight tolerances and intricate designs.

One of the main benefits of horizontal hydraulic powder forming is its ability to produce parts with uniform density and strength. Unlike traditional manufacturing methods such as casting or Machining, which can result in inconsistencies in material properties, hydraulic powder forming ensures that the final product is free from defects and has a consistent density throughout. This is crucial for industries that require parts with high structural integrity and reliability.

Another advantage of horizontal hydraulic powder forming is its ability to produce parts with minimal waste. Traditional manufacturing methods often result in a significant amount of material being wasted during the production process. In contrast, hydraulic powder forming allows for precise control over the amount of material used, resulting in minimal waste and lower production costs. This not only makes the process more environmentally friendly but also more cost-effective for manufacturers.

Another advantage of horizontal hydraulic powder forming is its ability to produce parts with minimal waste. Traditional manufacturing methods often result in a significant amount of material being wasted during the production process. In contrast, hydraulic powder forming allows for precise control over the amount of material used, resulting in minimal waste and lower production costs. This not only makes the process more environmentally friendly but also more cost-effective for manufacturers.

Horizontal hydraulic powder forming also offers greater design flexibility compared to traditional manufacturing methods. With hydraulic powder forming, manufacturers can easily create parts with complex geometries and intricate designs that would be difficult or impossible to achieve using other methods. This allows for greater innovation and creativity in product design, giving manufacturers a competitive edge in the market.

Furthermore, horizontal hydraulic powder forming is a highly efficient process that can significantly reduce production times. The hydraulic press used in this process can exert high Levels of pressure in a short amount of time, allowing for rapid production of parts. This is especially beneficial for industries that require quick turnaround times and high-volume production.

In addition to its efficiency and precision, horizontal hydraulic powder forming also offers improved material properties. The high pressure exerted by the hydraulic press during the forming process results in parts with enhanced mechanical properties, such as increased strength and durability. This makes hydraulic powder forming an ideal choice for industries that require parts with superior performance characteristics.

Overall, horizontal hydraulic powder forming offers a wide range of advantages for the manufacturing industry. From its ability to produce complex parts with high precision to its efficiency and cost-effectiveness, this innovative technology has transformed the way parts are manufactured. As industries continue to demand higher quality and more intricate components, horizontal hydraulic powder forming will undoubtedly play a crucial role in meeting these requirements and driving innovation in manufacturing.