Table of Contents

Benefits of Using Diamond Drill Milling Tools for CNC Internal Threads

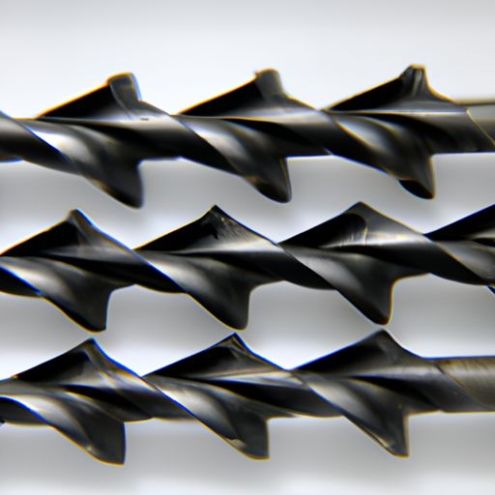

Diamond drill milling tools are essential for creating precise and accurate internal threads in CNC Machining. These tools are specifically designed to cut through hard materials such as Granite with ease, making them ideal for a wide range of applications in various industries. One of the key benefits of using diamond drill milling tools is their exceptional durability and longevity. Unlike traditional Drill Bits, diamond drill milling tools are made with high-quality diamond particles that are bonded to the cutting edge, ensuring a longer lifespan and superior performance.

Diamond drill milling tools are essential for creating precise and accurate internal threads in CNC Machining. These tools are specifically designed to cut through hard materials such as Granite with ease, making them ideal for a wide range of applications in various industries. One of the key benefits of using diamond drill milling tools is their exceptional durability and longevity. Unlike traditional Drill Bits, diamond drill milling tools are made with high-quality diamond particles that are bonded to the cutting edge, ensuring a longer lifespan and superior performance.

In addition to their durability, diamond drill milling tools offer unmatched precision and accuracy when creating internal threads. The diamond particles on the cutting edge of the tool allow for smooth and clean cuts, resulting in threads that are perfectly formed and free of imperfections. This level of precision is crucial in CNC machining, where even the smallest error can Lead to costly mistakes and delays in production.

Another advantage of using diamond drill milling tools for CNC internal threads is their versatility. These tools can be used on a wide range of materials, including granite, Marble, and other hard stones, as well as metals such as steel and Aluminum. This versatility makes diamond drill milling tools a valuable investment for any CNC machining operation, as they can be used for a variety of projects without the need for multiple tools.

One of the standout features of diamond drill milling tools is their ability to create internal threads in wet conditions. This is particularly useful when working with materials that generate a lot of heat during the cutting process, such as granite. The water-cooled design of diamond drill milling tools helps to dissipate heat and prevent overheating, ensuring a smooth and efficient cutting process. This feature not only improves the overall performance of the tool but also extends its lifespan by reducing wear and tear.

When it comes to choosing the right diamond drill milling tool for your CNC machining needs, quality is key. BAIXINTOOLS offers a range of high-quality diamond drill bits that are specifically designed for creating internal threads in hard materials. These tools are made with premium diamond particles that are carefully selected for their hardness and durability, ensuring a long-lasting and reliable performance.

In conclusion, diamond drill milling tools are an essential tool for creating precise and accurate internal threads in CNC machining. Their exceptional durability, precision, versatility, and ability to work in wet conditions make them a valuable investment for any CNC machining operation. When it comes to quality and performance, BAIXINTOOLS hot drill bits are the top choice for professionals looking to achieve superior results in their machining projects.

How to Properly Use Wet Core Drill Granite BAIXINTOOLS Hot Drill Bit for High Quality Results

Diamond drill milling tools are essential for CNC internal threading, as they provide precision and efficiency in creating high-quality threads. One such tool that stands out in the market is the Wet Core Drill Granite BAIXINTOOLS Hot Drill Bit. This tool is known for its durability, performance, and ability to deliver exceptional results in granite drilling applications.

When using the Wet Core Drill Granite BAIXINTOOLS Hot Drill Bit, it is important to follow proper procedures to ensure optimal performance and longevity of the tool. One key aspect to consider is the type of material being drilled. Granite is a hard and dense material that requires a specialized tool like the BAIXINTOOLS Hot Drill Bit. This tool is designed with diamond drill milling technology, which allows for smooth and precise drilling in tough materials like granite.

Before using the Wet Core Drill Granite BAIXINTOOLS Hot Drill Bit, it is important to prepare the surface by marking the drilling location and securing the material in place. This will help prevent any movement or slippage during the drilling process, ensuring accurate and clean results. Additionally, it is recommended to use a coolant or lubricant while drilling to reduce heat and friction, which can prolong the life of the tool and improve drilling efficiency.

When operating the Wet Core Drill Granite BAIXINTOOLS Hot Drill Bit, it is important to maintain a steady and consistent speed to prevent overheating and premature wear of the tool. The diamond drill milling technology of the BAIXINTOOLS Hot Drill Bit allows for fast and efficient drilling, but it is important to avoid excessive pressure or force, as this can damage the tool and compromise the quality of the drilled hole.

As you begin drilling with the Wet Core Drill Granite BAIXINTOOLS Hot Drill Bit, it is important to monitor the progress and adjust the speed and pressure as needed. The goal is to achieve a clean and precise hole without causing any damage to the material or the tool. By following these guidelines and using the BAIXINTOOLS Hot Drill Bit properly, you can achieve high-quality results in your granite drilling applications.

In conclusion, the Wet Core Drill Granite BAIXINTOOLS Hot Drill Bit is a top-of-the-line tool that is designed for precision and performance in granite drilling applications. By following proper procedures and using the tool correctly, you can achieve high-quality results and maximize the longevity of the tool. Whether you are a professional CNC operator or a DIY enthusiast, the BAIXINTOOLS Hot Drill Bit is a reliable and efficient tool that will help you achieve your drilling goals with ease.