Table of Contents

Benefits of Using 60 Degree Two Heads Carbide Center Drill Bit for Stainless Steel in CNC Cutting

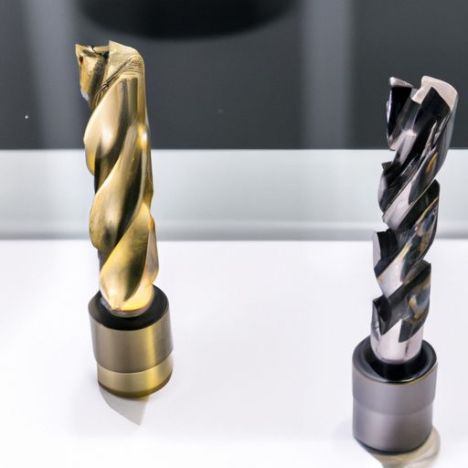

When it comes to CNC cutting, having the right tools is essential for achieving precision and efficiency. One tool that has gained popularity in the industry is the 60 degree two heads carbide center drill bit for stainless steel. This cutting tool offers a range of benefits that make it a valuable asset for any CNC Machining operation.

One of the key advantages of using a 60 degree two heads carbide center drill bit is its high precision. The carbide material used in the construction of the drill bit ensures that it maintains its sharpness and cutting edge for an extended period of time. This means that you can achieve consistent and accurate results with every cut, reducing the need for rework and improving overall productivity.

In addition to precision, the carbide center drill bit is also known for its durability. Stainless steel is a tough material to cut, but the hardness and strength of carbide make it well-suited for the job. This means that the drill bit can withstand the high temperatures and pressures involved in CNC cutting without losing its cutting edge. As a result, you can rely on this tool to deliver reliable performance over the long term.

In addition to precision, the carbide center drill bit is also known for its durability. Stainless steel is a tough material to cut, but the hardness and strength of carbide make it well-suited for the job. This means that the drill bit can withstand the high temperatures and pressures involved in CNC cutting without losing its cutting edge. As a result, you can rely on this tool to deliver reliable performance over the long term.

Another benefit of using a 60 degree two heads carbide center drill bit is its versatility. This cutting tool is designed to work with a wide range of materials, including stainless steel, Aluminum, and other metals. This means that you can use the same drill bit for a variety of cutting tasks, saving time and money on tool changes. Additionally, the two heads design allows for efficient drilling and chamfering in a single operation, further enhancing the tool’s versatility.

When it comes to price, the 60 degree two heads carbide center drill bit may have a higher initial cost compared to other cutting tools. However, the long-term benefits of using this tool far outweigh the upfront investment. The durability and precision of the carbide material mean that you will spend less on replacements and maintenance over time, saving you money in the long run.

Furthermore, the coating on the carbide center drill bit enhances its performance and longevity. The coating helps to reduce friction and heat buildup during cutting, which can prolong the life of the tool and improve cutting efficiency. This means that you can achieve faster cutting speeds and higher feed rates with the carbide center drill bit, leading to increased productivity and cost savings.

In conclusion, the 60 degree two heads carbide center drill bit for stainless steel is a valuable tool for CNC cutting operations. Its high precision, durability, versatility, and coating make it an excellent choice for cutting a wide range of materials, including stainless steel. While the initial cost may be higher, the long-term benefits of using this cutting tool make it a worthwhile investment for any machining operation.

How to Choose the Right Carbide Center Drill Bit for Stainless Steel JR123 with High Price Point

When it comes to drilling through stainless steel, having the right tools is essential to ensure a clean and precise cut. One of the most important tools in your arsenal is the carbide center drill bit. These specialized Drill Bits are designed to create accurate center holes in metal surfaces, making them ideal for stainless steel applications.

One popular option on the market is the 60 degree two heads carbide center drill bit for stainless steel JR123. This high-quality drill bit is specifically designed for use with CNC cutting tools and features a durable carbide construction that can withstand the tough demands of drilling through stainless steel.

One of the key features of the 60 degree two heads carbide center drill bit is its high price point. While this may deter some buyers, it is important to consider the quality and performance that you are getting in return for the investment. The high price point of this drill bit is reflective of its superior construction and precision engineering, making it a worthwhile investment for those who require top-notch performance.

The carbide construction of this drill bit ensures that it is able to withstand the high temperatures and pressures that are often encountered when drilling through stainless steel. This means that you can rely on this drill bit to deliver consistent and accurate results, even when working with tough materials.

In addition to its durability, the 60 degree two heads carbide center drill bit also features a specialized coating that further enhances its performance. This coating helps to reduce friction and heat buildup during the drilling process, resulting in smoother cuts and longer tool life.

When choosing a carbide center drill bit for stainless steel JR123, it is important to consider the specific requirements of your project. The 60 degree two heads carbide center drill bit is ideal for applications that require precise center holes, making it a great choice for CNC cutting tools.

It is also important to consider the size and shape of the drill bit, as this will impact the accuracy and efficiency of your drilling operations. The 60 degree two heads carbide center drill bit is available in a range of sizes to suit different applications, so be sure to choose the right size for your needs.

In conclusion, the 60 degree two heads carbide center drill bit for stainless steel JR123 is a high-quality tool that is well worth the investment. Its durable construction, specialized coating, and precision engineering make it a top choice for those who require reliable performance when drilling through stainless steel. By choosing the right carbide center drill bit for your project, you can ensure that you achieve the best results possible.