Table of Contents

Benefits of Using a 5W/10W CO2 Laser Cutting and Engraving Machine

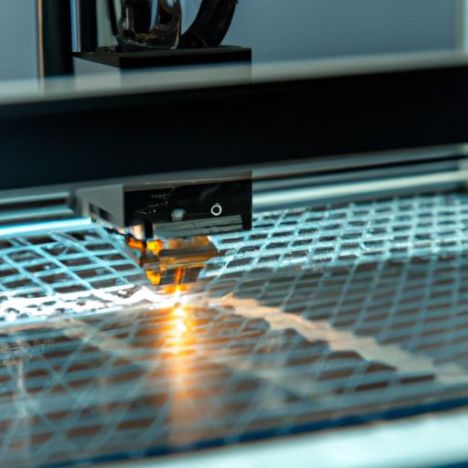

In the world of manufacturing and fabrication, precision and efficiency are key factors in producing high-quality products. One technology that has revolutionized the industry is the CO2 laser cutting and engraving machine. These machines use a high-powered laser beam to cut and engrave materials with incredible accuracy and speed. One popular model in the market is the 5W/10W CO2 Laser Cutting and Engraving Machine from Cloudray.

One of the main benefits of using a 5W/10W CO2 laser cutting and engraving machine is its versatility. These machines can cut and engrave a wide range of materials, including wood, acrylic, Leather, Fabric, and even metal. This makes them ideal for a variety of applications, from creating intricate designs on Jewelry to cutting precise patterns in industrial parts.

Another advantage of using a CO2 laser cutting and engraving machine is the precision it offers. The laser beam is controlled by a computer program, which allows for extremely accurate cuts and engravings. This level of precision is essential for industries that require tight tolerances and intricate designs.

In addition to precision, CO2 laser cutting and engraving machines are also known for their speed. The laser beam can cut through materials quickly and efficiently, reducing production time and increasing productivity. This is especially important for businesses that need to meet tight deadlines and produce large quantities of products.

Furthermore, CO2 laser cutting and engraving machines are easy to use and require minimal maintenance. Once the machine is set up and calibrated, it can run continuously without the need for constant adjustments. This makes it a cost-effective solution for businesses looking to streamline their production processes.

One of the key features of the 5W/10W CO2 Laser Cutting and Engraving Machine from Cloudray is its high power output. With a maximum power of 10W, this machine can cut through thick materials with ease, making it suitable for a wide range of applications. Whether you are cutting through acrylic sheets or engraving intricate designs on metal surfaces, this machine can handle the job with precision and efficiency.

Another feature that sets the Cloudray CO2 laser cutting and engraving machine apart is its user-friendly interface. The machine comes with a touchscreen control panel that allows operators to easily adjust settings and monitor the cutting process in real-time. This intuitive interface makes it easy for users to create complex designs and patterns with minimal training.

In conclusion, the 5W/10W CO2 Laser Cutting and Engraving Machine from Cloudray offers a range of benefits for businesses looking to improve their production processes. From its versatility and precision to its speed and ease of use, this machine is a valuable tool for industries that require high-quality cuts and engravings. With its high power output and user-friendly interface, the Cloudray CO2 laser cutting and engraving machine is a reliable and efficient solution for businesses looking to stay ahead in a competitive market.

How to Maximize Efficiency with Cloudray CO2 Laser Cutting Machine

Cloudray is a leading provider of CO2 laser cutting and engraving machines, offering a range of options to suit various needs and budgets. One of their popular models is the 5W/10W CO2 Laser Cutting and Engraving Machine, which is designed to provide high precision cutting and engraving capabilities for a wide range of materials.

When it comes to maximizing efficiency with the Cloudray CO2 Laser Cutting Machine, there are several key factors to consider. First and foremost, it is important to ensure that the machine is properly calibrated and maintained. This includes regularly cleaning the lens and mirrors, as well as checking and adjusting the alignment of the laser beam.

In addition to proper maintenance, it is also important to use the right settings and parameters for each material being cut or engraved. Cloudray provides detailed instructions and guidelines for setting up the machine for different materials, so be sure to follow these recommendations to achieve the best results.

Another way to maximize efficiency with the Cloudray CO2 Laser Cutting Machine is to optimize the cutting and engraving process. This includes using the right cutting speed and power settings, as well as ensuring that the material is properly secured and positioned on the cutting bed.

Furthermore, it is important to consider the design and layout of the cutting or engraving job. By optimizing the design and layout, you can minimize waste material and reduce the time it takes to complete each job. This can help increase productivity and overall efficiency with the Cloudray CO2 Laser Cutting Machine.

One of the key advantages of the Cloudray CO2 Laser Cutting Machine is its versatility. This machine can cut and engrave a wide range of materials, including wood, acrylic, leather, and more. By taking advantage of this versatility, you can expand the range of products you can create with the machine, thereby increasing your efficiency and profitability.

In addition to its cutting and engraving capabilities, the Cloudray CO2 Laser Cutting Machine also offers advanced features such as autofocus and rotary attachment options. These features can help streamline the cutting and engraving process, making it easier to achieve precise and consistent results.

Overall, the Cloudray CO2 Laser Cutting Machine is a powerful tool for maximizing efficiency in your cutting and engraving operations. By following proper maintenance procedures, using the right settings and parameters, optimizing the cutting and engraving process, and taking advantage of the machine’s versatility and advanced features, you can achieve high-quality results in less time and with less waste.

In conclusion, the Cloudray CO2 Laser Cutting Machine is a valuable investment for any business looking to maximize efficiency in their cutting and engraving operations. By following the tips and guidelines outlined in this article, you can make the most of this powerful machine and achieve impressive results in your cutting and engraving projects.