Table of Contents

Benefits of Using Wire Wound Resistors in Braking Systems

Wire wound resistors are a crucial component in braking systems, providing the necessary resistance to control the speed and efficiency of the braking process. These resistors are designed to withstand high temperatures and harsh conditions, making them ideal for use in automotive and industrial applications. One of the key benefits of using wire wound resistors in braking systems is their ability to provide precise and reliable braking resistance.

When it comes to braking systems, accuracy and consistency are essential. Wire wound resistors offer a high level of precision, allowing for precise control over the braking process. This is particularly important in applications where Safety is a top priority, such as in automotive braking systems. By using wire wound resistors, manufacturers can ensure that their braking systems operate smoothly and efficiently, reducing the risk of accidents and malfunctions.

In addition to their precision, wire wound resistors also offer a high level of reliability. These resistors are built to last, with a durable construction that can withstand the rigors of daily use. This reliability is essential in braking systems, where any failure or malfunction could have serious consequences. By using wire wound resistors, manufacturers can ensure that their braking systems will perform consistently and reliably, even in the most demanding conditions.

Another benefit of using wire wound resistors in braking systems is their versatility. These resistors can be customized to meet the specific requirements of a wide range of applications, making them suitable for use in a variety of industries. Whether it’s in automotive braking systems, Industrial Machinery, or other applications, wire wound resistors can be tailored to provide the precise resistance needed for optimal performance.

One of the key features of wire wound resistors is their digital insulation box. This innovative design helps to protect the resistor from external factors such as moisture, dust, and debris, ensuring that it remains in optimal condition for longer. The digital insulation box also helps to prevent overheating, which can Lead to premature failure of the resistor. By using wire wound resistors with a digital insulation box, manufacturers can extend the lifespan of their braking systems and reduce the need for costly repairs and replacements.

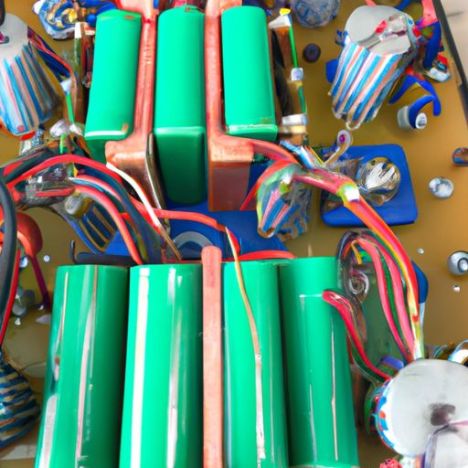

Wire wound resistors are also available in a range of power ratings, making them suitable for use in a variety of applications. For example, the 3kw alloy painted built resistor is designed to provide high power handling capabilities, making it ideal for use in heavy-duty braking systems. This resistor is built to withstand high temperatures and harsh conditions, ensuring that it will perform reliably under even the most demanding circumstances.

In conclusion, wire wound resistors offer a range of benefits for braking systems, including precision, reliability, versatility, and power handling capabilities. By using wire wound resistors in their braking systems, manufacturers can ensure that their systems operate smoothly and efficiently, reducing the risk of accidents and malfunctions. With their durable construction and innovative features such as digital insulation boxes, wire wound resistors are an essential component in modern braking systems.