Table of Contents

Benefits of Using the Heater T962C T-962C Intelligent BGA Rework Conveyor Reflow Soldering Station LED Heater

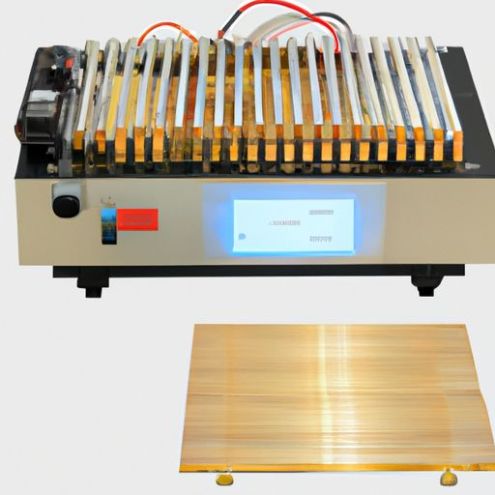

The Heater T962C T-962C Intelligent BGA Rework Conveyor Reflow Soldering Station LED Heater is a versatile and efficient reflow oven that offers a wide range of benefits for electronics manufacturers. This advanced piece of equipment is designed to streamline the soldering process, making it faster, more precise, and more reliable than traditional methods. In this article, we will explore some of the key benefits of using the Heater T962C T-962C Intelligent BGA Rework Conveyor Reflow Soldering Station LED Heater.

One of the main advantages of the Heater T962C T-962C is its intelligent design. This reflow oven is equipped with a range of advanced features that make it easy to use and highly efficient. The intelligent BGA rework conveyor ensures that components are heated evenly and consistently, reducing the risk of overheating or underheating. The LED heater provides precise control over the temperature, allowing for accurate soldering of even the most delicate components.

In addition to its intelligent design, the Heater T962C T-962C offers a large working area of 400x600mm, making it suitable for a wide range of applications. This spacious working area allows for the simultaneous soldering of multiple components, increasing productivity and reducing downtime. The reflow oven is also equipped with infrared IC technology, which ensures fast and efficient heating of components, resulting in high-quality solder joints.

Another key benefit of the Heater T962C T-962C is its conveyor system, which allows for automated soldering of components. This conveyor system can be programmed to move components through the reflow oven at a precise speed, ensuring that each component is heated for the correct amount of time. This automated process reduces the risk of human error and ensures consistent results every time.

The Heater T962C T-962C is also highly versatile, with the ability to solder a wide range of components, including BGA, QFN, and SMD components. This versatility makes it an ideal choice for electronics manufacturers who work with a variety of components and need a reflow oven that can handle different soldering requirements.

In addition to its intelligent design, large working area, conveyor system, and versatility, the Heater T962C T-962C is also highly reliable. This reflow oven is built to last, with a durable construction that can withstand the rigors of daily use. The LED heater is energy-efficient and long-lasting, providing consistent performance over time.

Overall, the Heater T962C T-962C Intelligent BGA Rework Conveyor Reflow Soldering Station LED Heater offers a wide range of benefits for electronics manufacturers. Its intelligent design, large working area, conveyor system, versatility, and reliability make it an ideal choice for those looking to streamline their soldering process and achieve high-quality results. Whether you are soldering BGA, QFN, or SMD components, the Heater T962C T-962C is a versatile and efficient reflow oven that can meet your needs.

Tips for Properly Operating the 400x600mm Reflow Oven Infrared IC

When it comes to operating the Heater T962C T-962C Intelligent BGA Rework conveyor reflow soldering Station LED Heater 400x600mm Reflow Oven Infrared IC, there are a few key tips to keep in mind to ensure optimal performance and results. This reflow oven is a powerful tool for soldering and reworking BGA components, and proper operation is essential for achieving consistent and reliable results.

One of the most important tips for operating the 400x600mm Reflow Oven Infrared IC is to carefully follow the manufacturer’s instructions and guidelines. This includes properly setting the temperature, conveyor speed, and other parameters to match the specific requirements of the components being soldered. Failure to follow these instructions can result in poor solder joints, component damage, or other issues that can compromise the quality of the finished product.

Another important tip is to properly preheat the oven before use. This helps to ensure that the temperature is stable and consistent throughout the reflow process, which is essential for achieving reliable solder joints. It is also important to allow the oven to cool Down properly after use, as rapid temperature changes can cause thermal stress on the components and Lead to reliability issues.

Properly loading the components onto the conveyor is also crucial for successful reflow soldering. Components should be placed evenly and securely on the conveyor to ensure that they are heated evenly and that they do not move or shift during the reflow process. It is also important to avoid overloading the conveyor, as this can lead to uneven heating and poor solder joints.

Monitoring the reflow process is another key aspect of operating the 400x600mm Reflow Oven Infrared IC. This includes regularly checking the temperature and conveyor speed to ensure that they are within the specified range, as well as monitoring the components for any signs of overheating or other issues. It is also important to keep a close eye on the solder joints as they reflow, as this can help to identify any potential issues early on and make adjustments as needed.

Proper maintenance of the reflow oven is also essential for optimal performance. This includes regularly cleaning the oven to remove any built-up flux or other contaminants that can affect the soldering process. It is also important to regularly calibrate the temperature and conveyor speed to ensure that they are accurate and consistent.

In conclusion, operating the Heater T962C T-962C Intelligent BGA Rework conveyor reflow soldering Station LED Heater 400x600mm Reflow Oven Infrared IC requires careful attention to detail and adherence to the manufacturer’s instructions. By following these tips and best practices, you can ensure that your reflow soldering process is efficient, reliable, and produces high-quality results.