Table of Contents

فوائد استخدام السخان T962C T-962C سخان LED الذكي لإعادة صياغة ناقل BGA ومحطة اللحام بإعادة التدفق

نصائح للتشغيل الصحيح لفرن إعادة التدفق مقاس 400 × 600 مم الذي يعمل بالأشعة تحت الحمراء IC

تعد الصيانة المناسبة لفرن إعادة التدفق أمرًا ضروريًا أيضًا لتحقيق الأداء الأمثل. يتضمن ذلك تنظيف الفرن بانتظام لإزالة أي تدفق متراكم أو ملوثات أخرى يمكن أن تؤثر على عملية اللحام. من المهم أيضًا معايرة درجة الحرارة وسرعة الناقل بانتظام للتأكد من أنها دقيقة ومتسقة. للتفصيل والالتزام بتعليمات الشركة المصنعة. باتباع هذه النصائح وأفضل الممارسات، يمكنك التأكد من أن عملية اللحام بإعادة التدفق فعالة وموثوقة وتنتج نتائج عالية الجودة.

Tips for Properly Operating the 400x600mm Reflow Oven Infrared IC

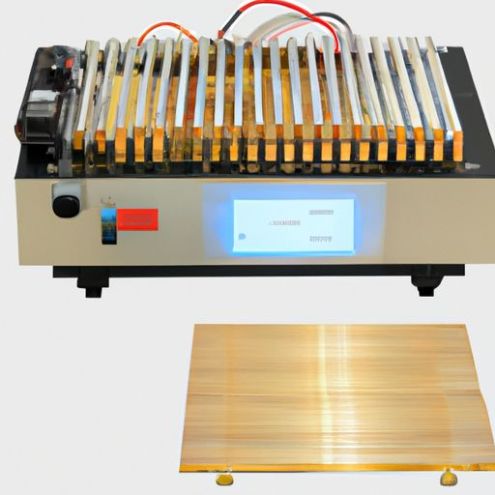

When it comes to operating the Heater T962C T-962C Intelligent BGA Rework conveyor reflow soldering Station LED Heater 400x600mm Reflow Oven Infrared IC, there are a few key tips to keep in mind to ensure optimal performance and results. This reflow oven is a powerful tool for soldering and reworking BGA components, and proper operation is essential for achieving consistent and reliable results.

One of the most important tips for operating the 400x600mm Reflow Oven Infrared IC is to carefully follow the manufacturer’s instructions and guidelines. This includes properly setting the temperature, conveyor speed, and other parameters to match the specific requirements of the components being soldered. Failure to follow these instructions can result in poor solder joints, component damage, or other issues that can compromise the quality of the finished product.

Another important tip is to properly preheat the oven before use. This helps to ensure that the temperature is stable and consistent throughout the reflow process, which is essential for achieving reliable solder joints. It is also important to allow the oven to cool Down properly after use, as rapid temperature changes can cause thermal stress on the components and Lead to reliability issues.

Properly loading the components onto the conveyor is also crucial for successful reflow soldering. Components should be placed evenly and securely on the conveyor to ensure that they are heated evenly and that they do not move or shift during the reflow process. It is also important to avoid overloading the conveyor, as this can lead to uneven heating and poor solder joints.

Monitoring the reflow process is another key aspect of operating the 400x600mm Reflow Oven Infrared IC. This includes regularly checking the temperature and conveyor speed to ensure that they are within the specified range, as well as monitoring the components for any signs of overheating or other issues. It is also important to keep a close eye on the solder joints as they reflow, as this can help to identify any potential issues early on and make adjustments as needed.

Proper maintenance of the reflow oven is also essential for optimal performance. This includes regularly cleaning the oven to remove any built-up flux or other contaminants that can affect the soldering process. It is also important to regularly calibrate the temperature and conveyor speed to ensure that they are accurate and consistent.

In conclusion, operating the Heater T962C T-962C Intelligent BGA Rework conveyor reflow soldering Station LED Heater 400x600mm Reflow Oven Infrared IC requires careful attention to detail and adherence to the manufacturer’s instructions. By following these tips and best practices, you can ensure that your reflow soldering process is efficient, reliable, and produces high-quality results.